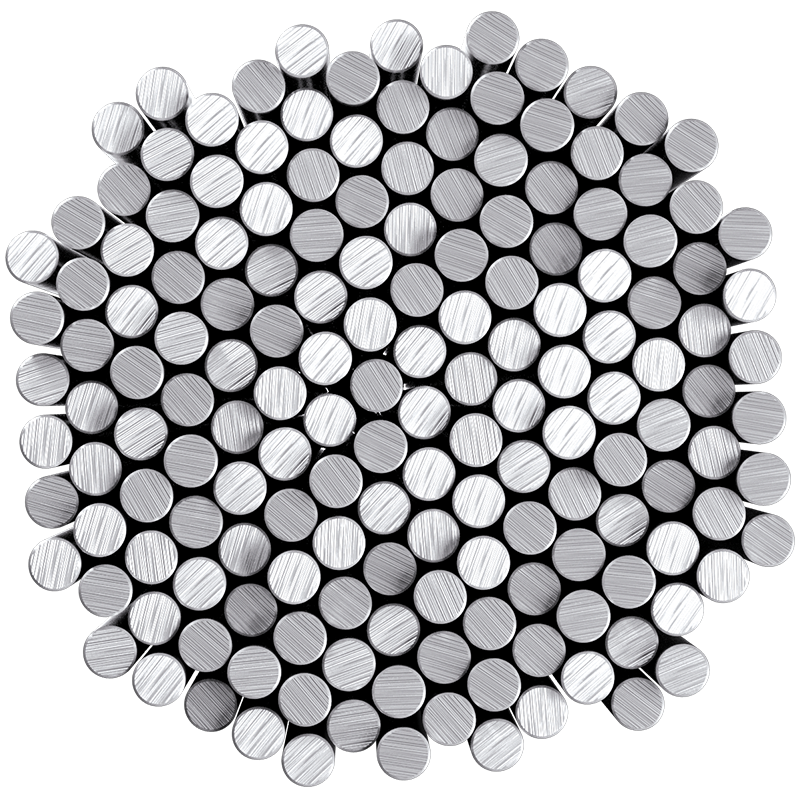

• Reliable range of Round bars

• Experienced team of professionals sagar industries is a leading Stainless steel Round bar manufacturer in India. Stainless steel bar beside having the characteristics or corrosions resistance has been developed over time to encapsulate end user applications. Sagar Industries produces Improved Machining (IM) grades that were developed to enhance machining of the steel into components, grades for hardness by responding to heat treatment and grades with high corrosion qualities by adding additional elements to give it the characteristics desired.

• Sagar industries produces Round bars with a comprehensive range of stainless steel grade and sizes of stainless steel Round bar to cover most machining and structural applications.

• Round Bar Manufactured For Corrosion Resistant Premium Quality – Designed For Excellence!

• Sagar industries is a pioneer in export quality stainless steel Round bars manufactured in India which sizes ranging from 2.5 mm to 100 mm diameter. We produce high ductility bolstering steel to avoid brittle failures while ensuring a high degree of safety. Our products are globally exported to more than 50 countries.